Buying an automated cable tester is like buying a new car. They cost about as much and can come with all sorts of intricate features. Like buying a car, if you don’t know the details beforehand you may feel intimidated by the information presented about different testers. Learning some basic facts about cable testers can improve your shopping experience and help you make the right choice.

1. What should a cable tester include?

The most basic automated cable tester should perform a continuity test checking for opens, shorts, and miswires. Most cable testers start with a basic unit that contains a set number of test points used to help connect your cable to the tester. Add-on units are often available to provide more test points for complex cables.

2. What specs should I pay attention to?

Specs let you know if the cable tester you are purchasing will meet your requirements. You may receive test specs either internal (standard to your production environment) or from a customer. Knowing what specs you need before you purchase a tester is very important.

Specs let you know if the cable tester you are purchasing will meet your requirements. You may receive test specs either internal (standard to your production environment) or from a customer. Knowing what specs you need before you purchase a tester is very important.

Some specs you should know:

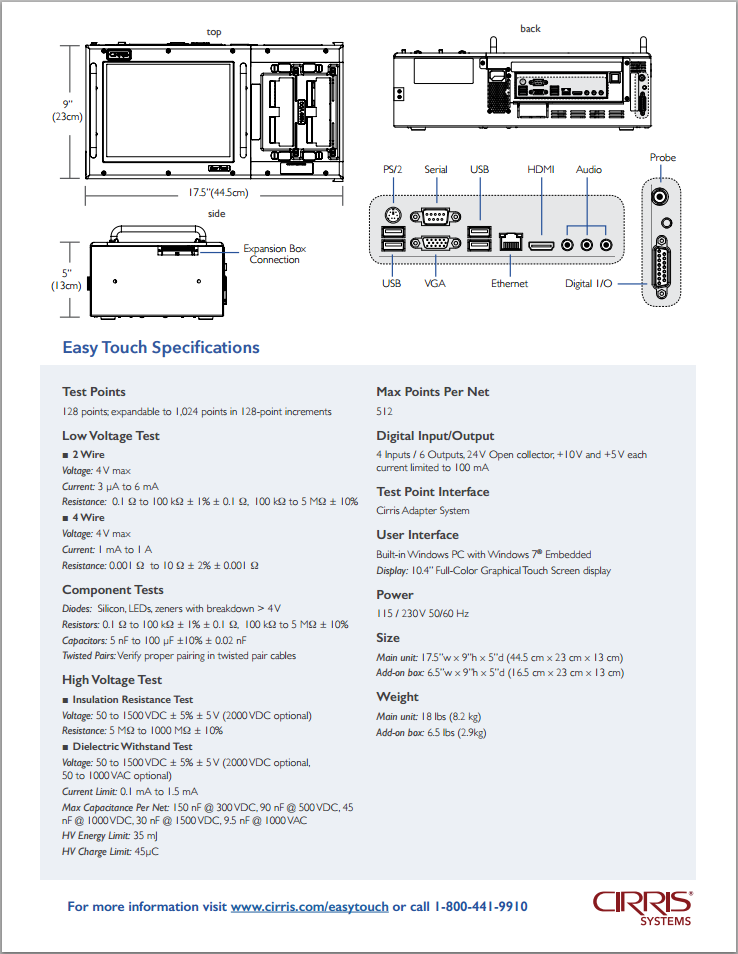

- Number of test points

- Voltage and current limits

- Tester dimensions

- Extra features such as

- High voltage

- 4-wire Kelvin

- Component testing

Even if you don’t understand all the numbers and symbols on the specs page, knowing points and voltage should give you a good guess at the tester you want. You can call a salesman to make sure you’ve chosen the correct tester to meet your needs.

3. Do I need high voltage?

Most companies divide testers into two categories, low voltage and high voltage. High voltage testers generally are more expensive but can be worth the extra money.

- Low voltage testers focus on continuity – they check that current flows from one point to another.

- High voltage testers focus on isolation – they check that current does not flow where it does not belong.

High voltage can find potential problems in cables such as defective insulation or terminal spacing problems. If you build cables for an industry where cable safety is a high priority, you may consider a high voltage tester.

Read this the this article to learn more about high voltage.

4. What type of connectors does the cable have?

You will need a way to connect the cable to the tester. If your cable has unique or complicated connectors attached, you will need to take this into consideration. Consult with the company salesman for methods to handle different connectors.

When you are armed with the right information, you will be sure make the right decision about which cable tester to buy. Remember that your cable tester is an investment that you will use for years to come.

Cirris has also put together a Tester Selection guide to help you decide which cable tester is right for your shop. This guide will ask questions about your specs and setting and provide options about which Cirris cable tester you may wish to purchase.