Rarely are cables built with connectors that can attach directly to the tester. For this reason, fixturing must be built to provide a way to connect the cable to the tester.

Fixturing refers to the wiring and cables between the device-under-test and the tester and can be a significant portion of the investment in a test system. Good fixturing is an essential part of ensuring the accuracy of test results and maximizes the test station’s throughput. This means fixturing needs to be at least as good, if not better than the quality of your device-under-test. Remember, you want to test the device-under-test, not test the fixturing.

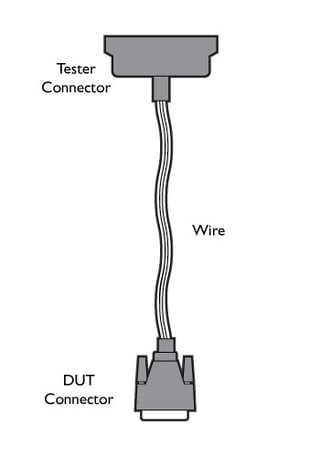

Fixturing contains three sections:

- Mates to the Tester Connector:This connector attaches to the tester and is required to meet conflicting requirements.

- The Wire:Insulation on these wires should not break down during a high voltage test and should continue to isolate even after exposure to constant handling and thousands of high voltage applications.

- Mates to the Device-Under-Test Connector:You have limited choices when building this connector because it must meet design considerations that are important to the device-under-test.

Mating Cycles

The quality of parts you use to build fixturing will affect the life of your fixturing. A connector can only take so many cycles before it no longer functions like it should. Cirris refers to these cycles as mating cycles.

Consider how often you will be able to replace parts and materials on your fixturing. You can buy cheaper parts and replace them more often or buy expensive parts that will last a long time.

Where can I obtain fixturing?

In shops with dedicated fixture building resources, the work can be accomplished by one person or department. In larger organizations, building fixturing becomes as hard as building high mix and low volume cable assemblies.

Cirris has seen how difficult it is for assembly shops to obtain parts and build fixturing. Many of these high mix low volume test shops produce fixtures. Although the prices can be higher for labor, the savings on this one-time setup cost could be worthwhile. If you are price sensitive and have available resources, you can purchase the materials and perform the labor yourself.

For example, Cirris has generic mating cables that only need to be terminated on one end. This can reduce labor and delivery times.